Zipper manufacturing machines can be divided into various types, each designed for specific functions in the zipper production process. Some common types of zipper manufacturing machines include:

Chain Making Machine: This machine is responsible for forming the chain of the zipper, which consists of individual interlocking teeth or elements. Modern chain making machines are equipped with precise mechanisms to ensure the teeth are uniform and durable.

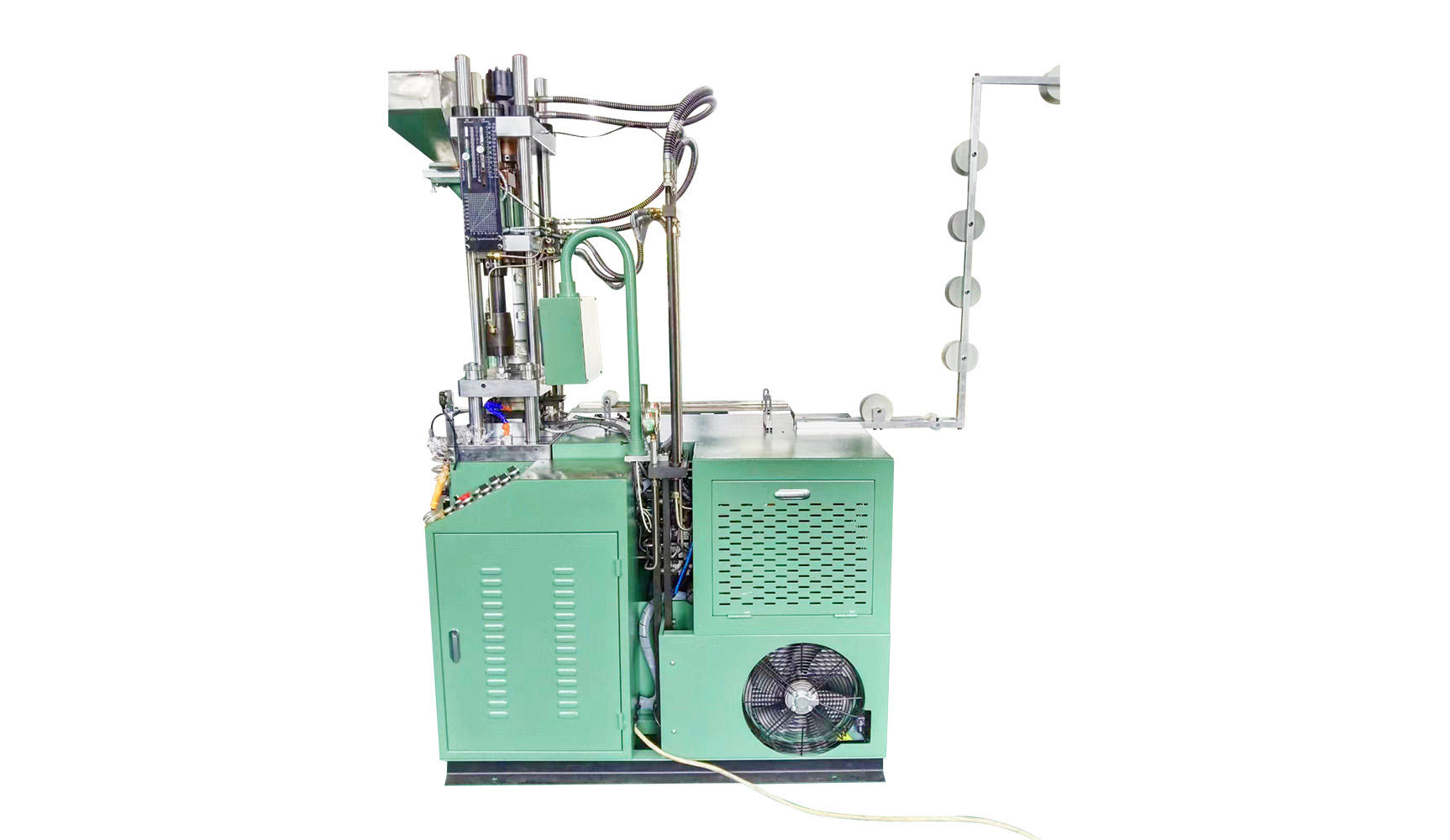

Slider Assembly Machine: The slider is the component that allows the zipper to open and close. Slider assembly machines automate the process of attaching sliders to the zipper chain. They need to ensure that the slider functions smoothly and securely.

Tape Attaching Machine: The tape is the fabric or material to which the zipper chain is attached. Tape attaching machines secure the chain to the fabric, ensuring that it is straight and properly aligned.

Finishing Machines: These machines perform various finishing tasks, such as cutting, sealing, and quality control. They help ensure that the zippers meet the required quality standards before they are ready for distribution.

The Zipper Manufacturing Process

The production of zippers involves several essential steps, and zipper manufacturing machines play a crucial role in each of these processes. Here's a brief overview of the typical zipper manufacturing process:

Wire Production: Zippers often begin as wire. The wire is treated and shaped to form the individual teeth or elements of the zipper. Wire processing machines are used in this stage.

Chain Making: The processed wire is then used to create the chain of the zipper. Chain making machines extrude, cut, and interlock the individual elements to form the continuous chain.

Slider Attachment: Slider assembly machines attach the sliders to the chain. Proper alignment and attachment are essential to ensure smooth operation.

Tape Attachment: The tape, which can be made of various materials including fabric, is attached to the zipper chain. Tape attaching machines secure the chain to the tape, ensuring it's straight and even.

Finishing and Quality Control: This step involves various finishing tasks, including cutting the zippers to the desired length, sealing the ends to prevent fraying, and performing quality control checks. Finishing machines are employed for these tasks.

Packaging: Once zippers have passed quality control, they are packaged and prepared for distribution to manufacturers of clothing, bags, and other products.

Technological Advancements in Zipper Manufacturing Machines

Zipper manufacturing machines have evolved significantly over the years, incorporating various technological advancements to improve efficiency, precision, and customization. Some notable advancements include:

Automation: Modern zipper manufacturing machines are highly automated, reducing the need for manual labor and increasing production efficiency. Automation ensures that zippers are produced consistently and with minimal errors.

Computer Numerical Control (CNC): CNC technology is used for precise control over cutting, molding, and other processes. It allows for customization and the production of zippers with complex designs.

Servo Motors: Servo motors offer precise control over the movements and forces applied during the manufacturing process. This ensures that each zipper is made with the correct timing and force.

Digital Quality Control: Zipper manufacturing machines are often equipped with digital quality control systems that can detect defects and irregularities in real-time, reducing waste and enhancing product quality.

English

English 中文简体

中文简体 Español

Español عربى

عربى