How have automatic injection molding machines transformed modern manufacturing, and what are the key factors contributing to their widespread adoption and success?

Automatic Injection Molding Machines: Catalysts of Change

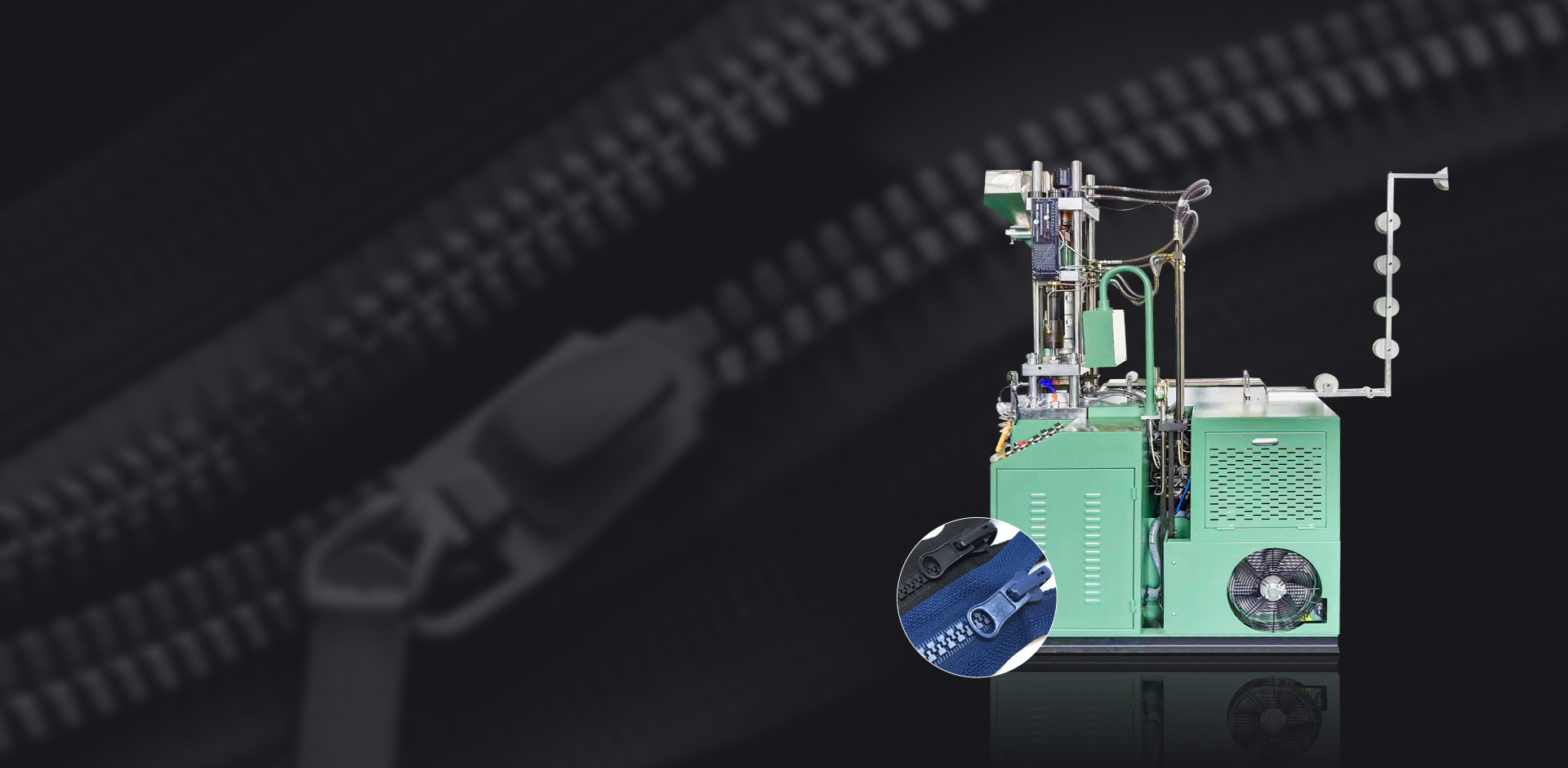

Automatic injection molding machines are a cornerstone of contemporary manufacturing. They are designed to automate and streamline the injection molding process, which involves injecting molten plastic or other materials into a mold to produce intricate plastic components. The transformative power of these machines is evident in the following ways:

1. Efficiency and Speed

One of the most noticeable impacts of automatic injection molding machines is their remarkable efficiency and speed. These machines are capable of producing large quantities of products rapidly. The reduction in cycle time for each part results in significantly higher production rates, enabling manufacturers to meet increasing demands efficiently.

2. Precision and Consistency

Automatic injection molding machines are engineered for precision and consistency. Computer-controlled systems monitor and adjust critical parameters, ensuring that every product adheres to strict quality standards. This level of precision is essential in industries where even minor variations can lead to defects and compromise product performance.

3. Cost Reduction

Automation in manufacturing leads to reduced labor costs. Automatic injection molding machines require fewer operators and can perform various tasks, such as material feeding, mold changes, and quality inspections, with minimal human intervention. As a result, operational expenses are minimized, contributing to cost-effectiveness.

4. Versatility

Modern automatic injection molding machines are highly versatile. They can produce a wide range of products with varying sizes, shapes, and complexities. The adaptability of these machines is a significant advantage, as they can be utilized across multiple industries, including automotive, electronics, consumer goods, and healthcare.

5. Waste Minimization

Automation and precise control systems help minimize material waste. These machines optimize the amount of material used for each product, reducing scrap and improving material utilization. This aligns with the increasing emphasis on sustainability in manufacturing.

6. Improved Safety

Automatic injection molding machines often incorporate safety features to protect operators. They are equipped with sensors and safeguards to prevent accidents and injuries, making the work environment safer for employees.

Factors Contributing to the Success of Automatic Injection Molding Machines

The success and widespread adoption of automatic injection molding machines can be attributed to several key factors:

1. Technological Advancements

Continuous advancements in automation technology have significantly improved the performance and capabilities of automatic injection molding machines. Innovations in control systems, robotics, and material handling have made these machines more reliable and efficient.

2. Quality Assurance

Modern manufacturers place a premium on quality assurance. Automatic injection molding machines' ability to consistently produce high-quality products with minimal defects has made them indispensable in industries where product reliability is paramount.

3. Customization and Adaptability

The versatility of automatic injection molding machines allows for customization and adaptation to meet specific product requirements. Whether it's producing intricate automotive components or simple consumer goods, these machines can be tailored to diverse needs.

4. Energy Efficiency

Efforts to reduce energy consumption in manufacturing have led to the development of energy-efficient automatic injection molding machines. These machines are designed with eco-friendly considerations, helping manufacturers reduce their environmental footprint and operating costs.

5. Rapid Production

The ability to produce a high volume of components quickly has allowed manufacturers to keep up with consumer demand and market fluctuations. This is especially vital in industries with rapidly changing trends and customer preferences.

6. Reduced Human Error

Automation significantly reduces the risk of human error in the production process. Automatic injection molding machines follow precise instructions, minimizing variations and defects that can result from manual handling.

English

English 中文简体

中文简体 Español

Español عربى

عربى