Historical Perspective:

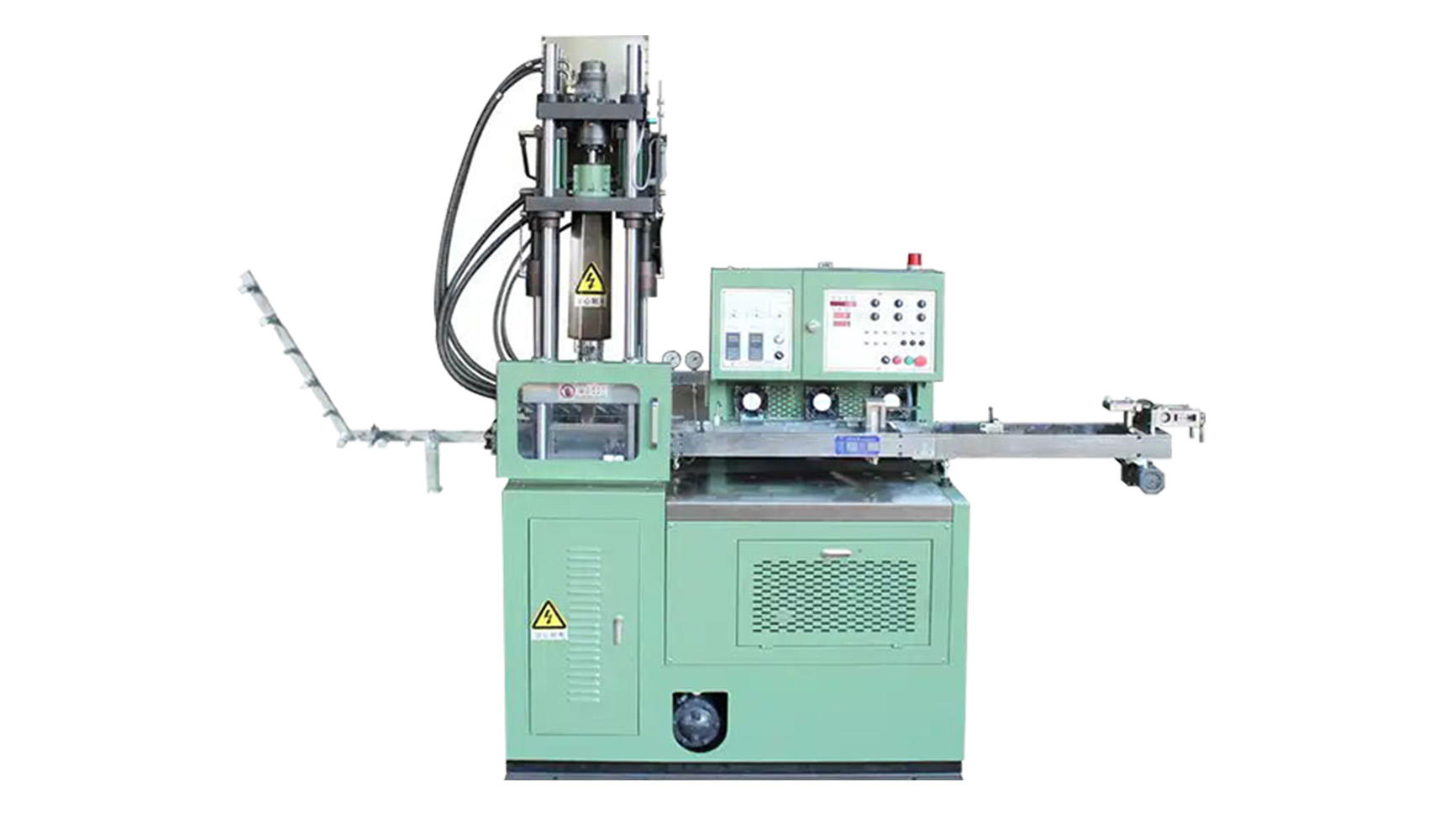

The fashion industry has long relied on traditional sewing and finishing techniques, including the use of zippers. These techniques are often labor-intensive and time-consuming, leading to inefficiencies in the manufacturing process. The introduction of advanced Zipper machines represents a significant departure from these traditional methods.

Current Impact of Zipper Machines:

Manufacturing Efficiency: Zipper machines, equipped with automation and precision technology, have greatly improved manufacturing efficiency. They can rapidly attach zippers to garments, reducing the time required for sewing and finishing.

Consistency and Quality: Automation ensures that zippers are attached consistently and securely, leading to higher product quality. This reduces defects and returns, enhancing customer satisfaction.

Customization and Creativity: Advanced Zipper machines offer a wide range of customization options, enabling designers to experiment with unique zipper styles, colors, and placements. This fosters creativity and innovation in fashion design.

Sustainability: Sustainable practices are a growing concern in the fashion industry. Some Zipper machines use eco-friendly materials, reduce fabric waste, and lower energy consumption, contributing to sustainability efforts.

Cost Reduction: By streamlining manufacturing processes and reducing labor costs, Zipper machines can help fashion brands maintain competitive pricing while improving profit margins.

Supply Chain Integration: Zipper machines, when connected to digital systems, can provide real-time data on production progress, enabling more efficient supply chain management.

Future Implications:

Sustainable Materials: The use of sustainable materials in Zipper machines is likely to become more prominent. This will align with the fashion industry's sustainability goals and customer demand for eco-friendly products.

AI and Machine Learning Integration: Zipper machines of the future may incorporate AI and machine learning algorithms for even more precise attachment, quality control, and predictive maintenance.

On-Demand Manufacturing: The fashion industry could move towards more on-demand manufacturing models, where garments are produced as orders come in. Zipper machines will play a crucial role in facilitating this shift.

Collaborative Robotics: The integration of collaborative robots (cobots) into Zipper machines could make them more flexible, enabling them to work alongside human operators on complex tasks.

Digital Twins: Zipper machines may be paired with digital twin technology, allowing for real-time simulation and optimization of manufacturing processes.

Ethical and Sustainable Supply Chains: The fashion industry is placing a greater emphasis on ethical sourcing and sustainable supply chains. Zipper machines could be part of the solution by ensuring that all components, including zippers, are ethically and sustainably sourced.

Consumer Personalization: As Zipper machines offer more customization options, fashion brands may enable consumers to personalize their garments, from zipper styles to placements, directly at the point of purchase.

the automation of the textile and fashion industry through advanced Zipper machines is enhancing manufacturing efficiency, product quality, and sustainability. The future of fashion manufacturing will likely see even greater integration of automation, sustainability, and customization. As the industry evolves, Zipper machines will remain at the forefront, enabling fashion brands to meet consumer demands for high-quality, sustainable, and unique clothing.

Zipper machines can be part of the solution by ensuring that all components, including zippers, are sourced ethically and sustainably. The fashion industry is increasingly focusing on ethical sourcing and sustainable supply chains.

English

English 中文简体

中文简体 Español

Español عربى

عربى